The BART Communications Based Train Control (CBTC) is part of a broader Transbay Corridor Core Capacity Program (TCCCP), which, in addition to CBTC, includes 252 additional railcars, a new railcar storage yard and five new traction power substations. On December 3, 2015, the BART Board authorized the General Manager to issue solicitation documents for a CBTC system using the Design-Build method of procurement. The state-of-the-art CBTC system will increase transit capacity and improve reliability by replacing aging equipment.

View the October 12, 2023 project update presentation to the Board of Directors. Watch the video of the presentation above.

Why Invest in CBTC?

CBTC is a proven railway signaling system that makes use of the telecommunications between the train and trackside equipment for the traffic management and infrastructure control. By means of the CBTC systems, the exact position of a train is known more accurately than with the traditional fixed block signaling systems. CBTC allows for real-time adjustments of speed and braking to allow for safe train separation while allowing trains to get closer to each other. This equates to increased capacity and thus reduced wait times between trains. A modernized train control system will enable BART to increase projected Transbay capacity to 30-trains per hour per direction in the core system area, from the current limitation of 24-trains per hour per direction.

Federal dollars to expand the System’s Transbay capacity were approved on September 16, 2020. BART awarded a design build contract to Hitachi Rail STS USA, Inc. on September 30, 2020 and issued a Notice to Proceed on November 2, 2020, which will take about eleven years to complete. The new CBTC technology will first be proven on a test track and then will roll out for BART mainline deployment in eight geographical phases, with the ability to run 28 trains per hour in each direction through the Transbay Tube in 2030 and up to 30 trains in 2032. BART and Hitachi have been working together on the Conceptual Design Phase work products, which will set the foundation for Preliminary Design which will begin in the Spring of 2021. The team is also preparing for early surveys of field conditions and developing plans for equipping the test tracks with CBTC components. Hitachi completed Conceptual Design in the spring of 2021 and is now advancing Preliminary Design. The team has continued to engage in field survey work to verify as-built conditions in order to help initiate installation design. Rosendin Electric, a subcontractor to Hitachi, is documenting potential electrical conduit pathways and potential pathways for microduct installation at various locations in and around the stations. In addition, the team is moving forward in performing in housework on Enabling Works replacing 50 year old cable to wayside interlocks and Train Control Room Power. The installation work will be performed by BART labor, with the procurement of material and service contracts to support BART’s install.

This CBTC system's 10-step implementation phase will bring continuous change to BART and the riding public. To support the successful implementation of the Hitachi CBTC Design-Build Contract, BART selected two engineering consultant teams, Parsons and Systra/Hatch, to provide Design Support During Construction (DSDC) services including technical design, engineering, project management and implementation oversight support. In addition, BART selected two construction management firms, Jacobs Engineering Group Inc. and CPM Associates, Inc., to provide General Construction Oversight services.

Electric group surveying and documenting with photos pull boxes and wireways

BART support opened the covers of pull boxes/wireways

Micro-Duct team verifying potential Micro-Duct required length

Electrical and micro-duct team surveying and documenting with photos potential cable pathways in manhole

Electrical team documented and took pictures of the panel locations inside a substation

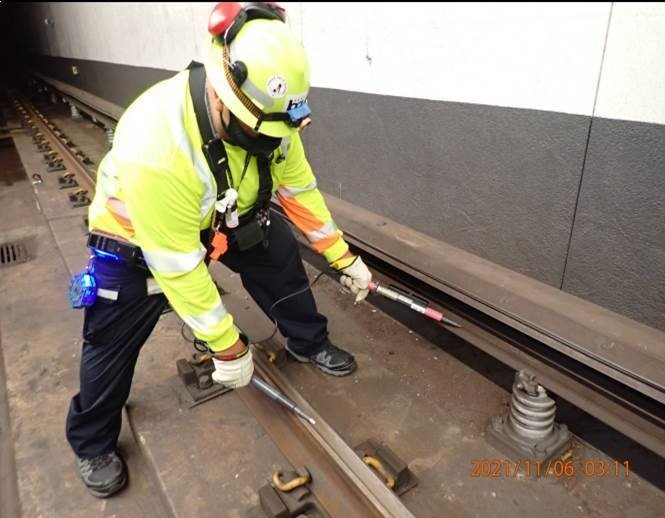

Staff verifying that the third rail is turned off