The Science of Cleaning: New training program helps station cleaners shine up their skills

Cleaning Management Institute trainer Marion Ivey leads a class for BART cleaners

Cleaning Management Institute trainer Marion Ivey leads a class for BART cleaners

By MELISSA JORDAN

BART Senior Web Producer

Most of us learned cleaning from our parents, and may follow their example: Do you use a sponge or cotton-string mop? A canister or upright vacuum? Bleach or vinegar?

Professional custodians in commercial or industrial settings, like those who clean BART stations, must learn specialized best practices to maximize their efficiency and safety. A new program at BART is giving station cleaners (known as System Service workers in BART parlance) an extremely detailed, interactive, rigorous training covering everything from chemistry to virology to ergonomics.

I sat in with one group of cleaners going through the training; a small class size of eight people gave each person lots of time to ask questions and do hands-on tests of their skills inside an actual station. At the end of four days of training, 32 hours in all, they get a certification from the Cleaning Management Institute (CMI), an internationally recognized association dedicated to high industry standards. Their teacher is Marion Ivey, recently named Trainer of the Decade by CMI, who has close to 30 years of experience teaching about cleaning.

“When I started my teaching career, never in my wildest imagination could I have predicted how today’s industry would evolve,” Ivey said. “I’ve observed technological advancement in equipment, materials, and supplies. New technologies also have created a need for changing basic and advanced work procedures.” Jeff Gon, a BART cleaning trainer, was sitting in on Ivey’s classes to make sure the best practices are put into place after the initial training period is completed. “We’re working to make sure we are all on the same page,” Gon said. “In the past, over BART’s 46 years, training for cleaners wasn’t always consistent.”

Members of the eight-person class concurred – including three cleaners who each had around 25 years of experience at BART. One had been shown the ropes informally by a supervisor when he was first hired. Another had a new-hire session and online class reviews. Another remembered simply being dropped off at a station and told to go to work. Those days, from decades ago, are over. Now, all the existing cleaners as well as all new hires will go through this intensive hands-on class.

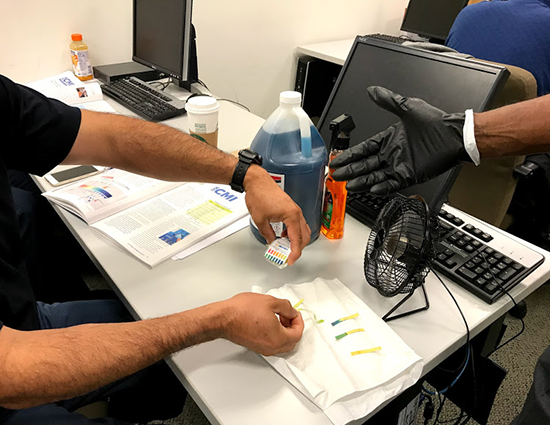

Ivey helps a student test the chemistry of a cleaning solution using litmus strips

On Day 2, they were studying a module called “The Chemistry of Cleaning.” Ivey walked the room, giving each person a chance to use a litmus strip to test acidity or alkalinity of a substance. “I want you to get used to looking at labels,” Ivey told them. “Read the Safety Data Sheets. You need to know the makeup of what you’re cleaning, so you can choose the right supplies, materials and equipment.”

“This class is huge,” said student Phil Corsetti, a 25-year veteran cleaner. “It’s a good sign of commitment from management to doing things in a consistent way.” “It has been really eye-opening,” said student Milton Bradford, another cleaning veteran. “I’m going to be much more conscious of how I’m handling supplies.”

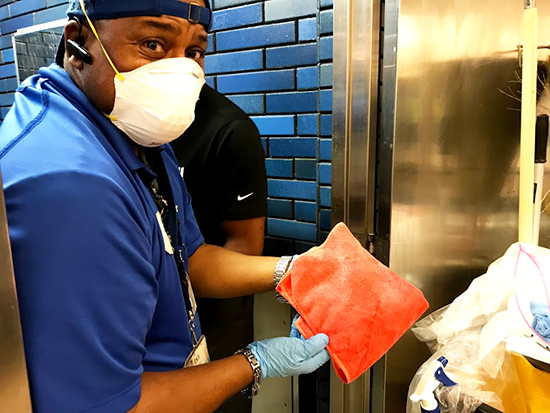

Milton Bradford wears Personal Protective Equipment on a field trip to a station.

Milton Bradford wears Personal Protective Equipment on a field trip to a station.

The group left the classroom in the afternoon for a hands-on field trip to a station. Half the group stayed with Ivey to demonstrate proper cleaning of a restroom (a 14-step process) while the other half went with Gon to wipe down escalator handrails and other surfaces using proper cleaning techniques (first wipe up and down, then side to side). Then the groups switched so each could get both experiences. They used their proper Personal Protective Equipment, including masks and gloves when needed, and ultimately left those areas immaculate, although it’s a never-ending process as throngs of people (more than 400,000 every day) ride BART.

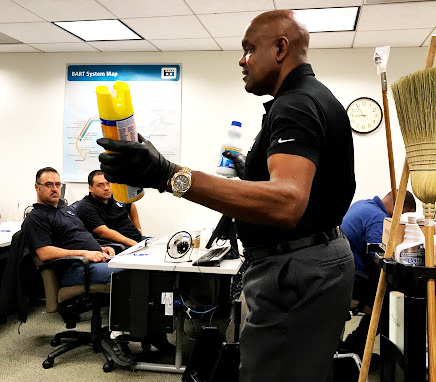

“BART has a unique environment,” Ivey said. “You’ve got hundreds of thousands of people coming through, brake dust, spills, biowaste, and so many different types of surfaces.” With a fully loaded cleaning cart for props, Ivey grilled them on what steps to take in different situations, and made sure they knew the purpose of each product. For example, they learned that bleach is a disinfectant, but not a cleaner per se, and that a good, all-purpose general cleaning solution is indispensable. “What do you do with that when you need it?”, he queried.

“I have to clean it first with a cleaner, then come back and disinfect it,” one student answered. “That’s right!” Ivey encouraged. “Stop it, then eradicate it. You are empowered to know that if it’s in your inventory, you’ll know what to do with it.”

They talked about using enzyme materials to absorb malodors, kitty-litter-type granules for liquids, steam vapor for stubborn grime, and microfiber cloths that grab dust and don’t let go.

Ivey holds a can of Lysol in the training class

“YOU are the change-makers,” Ivey told the class. “You can make a huge difference in your job to the public that rides BART.” Gon emphasized that the training should make the job of the cleaners, already unsung heroes, more fulfilling and sustainable. It’s hard work that takes a toll on the body.

“They’re going to be more efficient, spending less time per surface because they’re using the right products and tools, and have less wear and tear on their bodies,” he said. “In the past everyone had different experiences and they may not have known the best practices. We’re going at it in a systematic way now, and elevating their professionalism.”

The training could help cleaning be more economical as well, an important consideration for good oversight of resources. For example, students learned about proper dilution of cleaning solutions – in the past some noted they may have used lesser dilutions, essentially using more product than was effective or even necessary. They pulled out calculators on their phones to do the math for proper dilution.

At the end of the week-long class, after passing a written test and demonstrating their mastery of skills, the cleaners get an embossed certificate and a patch that shows they are CMI-certified. “It’s not just a flimsy piece of paper,” Ivey said. “It’s on card stock. They’re cleaning professionals and they are being held to exacting standards.”