In 2012 BART chose Bombardier Transit Corporation (now Alstom) to build BART's Fleet of the Future—a complex design, engineering, supply chain, and assembly process. In January 2018, the first ten train cars began service following safety and reliability testing, and regulatory approval.

Design, Test and Manufacture

The process of designing and manufacturing new BART train cars is long and includes many phases. The first step was to design the new train cars from the ground up. BART is a unique rail system that has the lightest train car for its size in the United States. While this makes BART cars the most efficient, it also means that a typical off-the-shelf solution does not meet the needs of the Bay Area.

The next step of the process was the manufacture and test of the equipment for installation on the new trains. Lab tests occurred on all internal systems including the propulsion systems, brakes, motors, and heating and cooling systems to make sure they are capable of performing to the highest standards.

In 2017, BART tested 10 pilot cars on BART test tracks and throughout the BART system to ensure safety and reliability, and to secure approval from the California Public Utilities Commission to run passenger service. Much of the testing was outside of normal operating hours. During this thorough qualification and testing phase, BART and Bombardier verified and validated the train car performance prior to full-scale manufacturing.

Upon successful completion of initial testing, these pilot cars were put into revenue service.

Why Bombardier?

After a year-long evaluation process in which two separate and independent teams evaluated more than 500 aspects of the three final bids, the independent teams selected Bombardier (later acquired by Alstom) based on its technical capabilities and low cost. Bombardier's bid came in 12% lower than the next least expensive bid, saving BART $184 million—equivalent to the cost of 104 train cars.

Buy America

The Federal Transit Administration (FTA) requires that domestic components account for at least 60% of the total cost of all components used to build new transit vehicles and that final assembly take place in the USA.

In 2011 California Governor Jerry Brown signed a BART-sponsored bill that authorizes California public agencies to establish bid preferences for train car proposals that exceed minimum federal requirements for domestic content. BART is proud to have been the first transit agency in the nation to give "extra credit" to bids that exceed the federal 60% domestic content requirement. As a result, the new cars will meet a 66% Buy America standard.

Companies in the United States are supplying many of the materials and parts used in the train cars, including the propulsion system, the brakes, the raw aluminum used for the body, and much of the electrical wiring.

Final assembly of the new train cars is taking place in New York State, but will be transferred to the Bay Area over the coming months. (Federal contracting provisions prohibit BART from placing any requirements on where in the U.S. assembly takes place or parts are manufactured.)

In conjunction with BART's new train cars, hundreds of new American assembly jobs have been created. Here locally, Bay Area jobs support the design, commissioning, warranty and other activities associated with the project.

Project Timeline

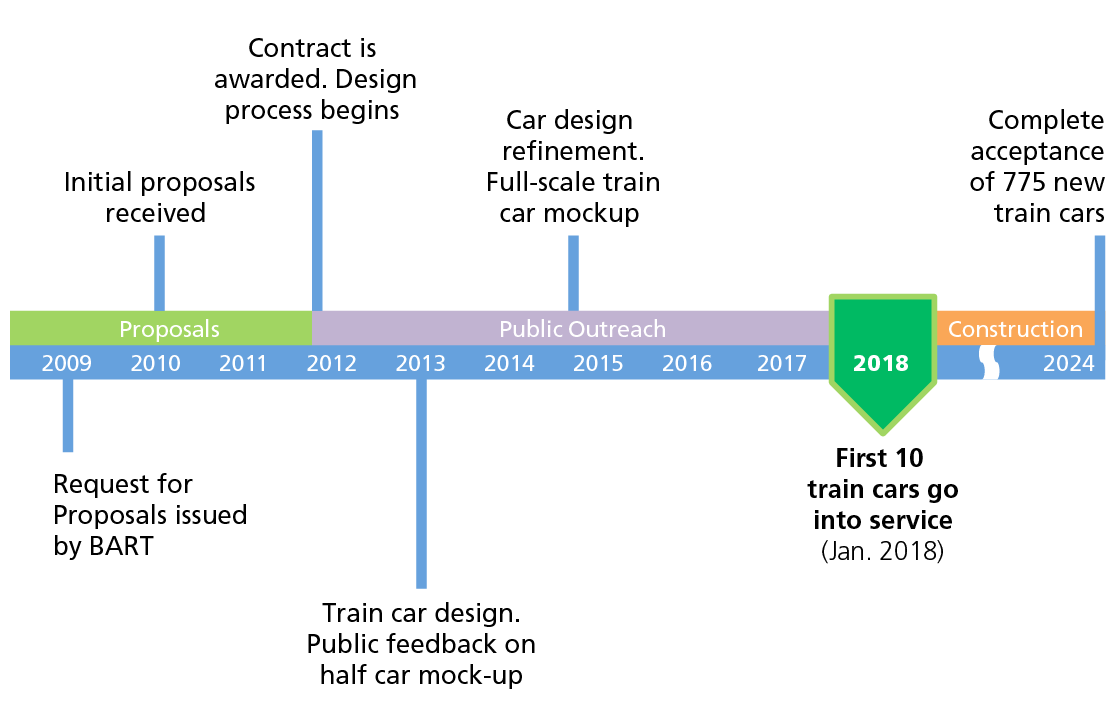

- BART's 2009 Request for Proposal was a formal request for qualified companies to submit a comprehensive bid for the new train cars. The RFP provided detailed technical and commercial requirements.

- Proposals from competing companies were submitted to BART for review in 2010. Over the course of the year BART undertook an evaluation and clarification process with each of the bidders that culminated in the BART issued Request for Best and Final Offers (BAFO) in 2011.

- In early 2012 BART received and evaluated all BAFO proposals. Later that year the BART Board of Directors voted unanimously to choose Bombardier Transit Corporation as the car builder for BART's Fleet of the Future.

- After the car builder selection, a detailed design process began, incorporating customer feedback.

- In Summer 2013, during the design process, BART brought a full scale, half-car wooden model and prototype seats to the Bay Area for customers to try out and provide feedback. The feedback was used to refine the design.

- In Spring 2014, over 17,000 customers tried out a final full-scale, half-car model of the new train car at events around the Bay Area. The feedback was used to make final design modifications.

- In 2017 ten pilot cars were comprehensively tested on the BART system.

- In January 2018, the first 10-car train began revenue service.

- As of May 2019, BART has on 10-car train available on each transbay BART line, plus an 8-car train on the Richmond/Warm Springs route.

- Over the next several years, production will ramp up to a rate of 16 new cars per month. Current forecast indicates the delivery of new train cars completed in 2024, bringing BART's new fleet to a total of 775 train cars. (Some older cars will continue to remain in service.)

- BART's goal is to ultimately obtain enough funding to increase the fleet to 1,200 new train cars.

- On Nov 15, 2018, the BART Board of Directors unanimously authorized the negotiation for sole source procurement of additional train cars from Bombardier beyond the original contract of 775 cars, with options allowing up to a total of 1,200 new cars.

- On January 8, 2021, BART temporarily stopped accepting delivery of new Fleet of the Future (FOTF) rail cars to allow the manufacturer, the time to take steps to improve the cars’ reliability and availability, and to alleviate rail car storage constraints at BART’s maintenance yards.

- In February 2022, BART resumed accepting deliveries of new Fleet of the Future rail cars following some major reliability issue sufficiently resolved by the manufacturer. During the pause in deliveries, BART and the manufacturer have made necessary upgrades and modifications. These changes, along with several software improvements, have significantly improved the overall performance of the new cars.

Rail Car Procurement Project (Phases 1 and 2) Funding

In 2012, the BART Board of Directors awarded a contract to Bombardier Transit Corporation (later acquired by and hereinafter referred to as Alstom) for the design and construction of BART’s Fleet of the Future rail cars, the Rail Car Procurement Phase 1 Project (Phase 1 Project). In May 2012, the BART Board gave the go ahead to acquire 410 new state-of-the-art Fleet of the Future rail cars. In November 2013, the BART Board voted to authorize the procurement of an additional 365 rail cars.

Of the 775 total rail cars procured under this first Fleet of the Future procurement contract, 669 were to replace BART’s legacy fleet with new rail cars, 46 to expand the fleet, and 60 – fully funded by the Santa Clara Valley Transportation Authority (VTA) – to support BART service for the first phase of VTA’s BART to Silicon Valley project.

The original cost estimate for the Phase 1 Project was $2.58 billion. In Fall 2024, BART announced cost savings on the Phase 1 Project of nearly $400 million, resulting in an updated cost estimate of $2.18 billion.

The Phase 1 Project is being delivered with the support of multiple federal, state and local funding and financing sources:

- Federal Formula Section 5307/ 5337 Funds

- Federal Congestion Mitigation and Air Quality Program (CMAQ) Funds

- Transportation Infrastructure Finance and Innovation Act (TIFIA) Loan Proceeds

- State of California Low Carbon Transit Operations Program (LCTOP) Funds

- State of California Prop 1A High Speed Rail Funds

- Santa Clara Valley Transportation Authority (VTA) Funds

- State of California Affordable Housing and Sustainable Communities (AHSC) Program Funds

- Regional Measure 2 (RM2) Bridge Tolls

- AB664 Bay Area Bridge Tolls

- Metropolitan Transportation Commission (MTC) Provided Financing Proceeds

- BART Car Replacement Funding Exchange and Reserve Account

- BART Funds

On November 15, 2018, the BART Board approved a sole source procurement with Alstom of up to 425 additional rail cars, the Rail Car Procurement Phase 2 Project (Phase 2 Project), for an amount not to exceed $1.167 billion to increase the overall size of the District’s next generation fleet of rail cars to up to 1,200. On September 20, 2020, the District signed a notice to award a base contract of 100 rail cars to Alstom for $258,535,000. Subsequently, the District executed three options for a total of an additional 354 rail cars:

- Option 1 on February 13, 2023, for 152 rail cars for $371,617,200

- Option 2 on December 14, 2023, for 54 rail cars for $132,012,000

- Option 3 on May 24, 2024, for 48 rail cars for $117,352,800.

Upon completion of the Phase 2 Project, BART will have a total of 1,129 Fleet of the Future rail cars. BART did not execute Option 4. The 306 rail cars purchased under the Phase 2 Project base contract and options 1 and 2 will enable BART to run longer, more frequent trains as part of its Core Capacity Program for an aggregate 40% capacity increase in the core of the BART system. The 48 rail cars purchased under option 3 are fully funded by VTA and will support the second phase of VTA’s BART to Silicon Valley Extension.

The Phase 2 Project is estimated to cost $1.28 billion and is also funded with multiple funding sources:

- FTA Capital Investment Grant (CIG) Funds

- State of California Transit and Intercity Rail Capital Program (TIRCP) Funds

- Regional Measure 3 (RM3) Bridge Tolls

- San Francisco County Transportation Authority Proposition L Sales Tax Revenues

- Alameda County Transportation Commission Measure BB Sales Tax Revenues

- BART Car Replacement Funding Exchange and Reserve Account

- BART Funds