New parts warehouse at Hayward Maintenance Complex earns LEED Silver Certification

Photo of Hayward Central Warehouse courtesy of Clark Construction Group

By MELISSA JORDAN

BART Senior Web Producer

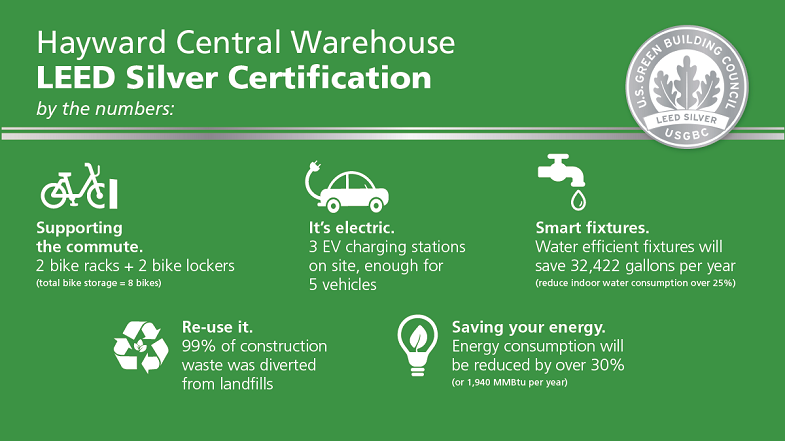

A new Central Warehouse in Hayward where BART stores District materials has earned LEED Silver Certification, showing that the building reflects state-of-the-art best practices in sustainability.

Features like energy-efficient HVAC and lighting will cut energy consumption by more than 30%. Landscape design will reduce outdoor water consumption by more than 80%, more important than ever as our state faces drought and impacts of climate change. The layout of the building is also more efficient for operations, facilitating the receipt, storage and location of critical components required to keep trains rolling with fewer equipment-related delays, resulting in a better customer experience for BART riders.

“It is exceedingly simple, utilitarian, and it works,” said Roland Fowlks, the Logistics Manager who oversees the District’s Logistics and Stores operation. “We have much better utilization of the space. From a workflow standpoint, it’s a huge improvement.” BART is transitioning its primary warehouse and distribution operation from a maintenance shop location, which dates to the start of the system in 1972, and which by comparison is congested and not always easy to get around. “We’re in the process of moving inventory from one location to another,” Fowlks said, “to turn the warehouse into our central distribution and receiving point by late summer.”

The new warehouse has more than 100,000 square feet of storage, and is reminiscent of a Costco or Ikea on steroids. It is brightly lit and is kept organized with modern digital inventory systems. It’s like going from using an old, paper card-catalogue system to find your library book to using an online system to search all the stacks in a split second online. In addition, the site offers environmentally friendly amenities for workers such as an outdoor seating area, secure bike storage and electric vehicle charging stations, which both encourage low-carbon transportation to the site. When fully operational, the warehouse will be the job site for at least 30 workers across multiple shifts.

Bike storage and showers onsite encourage active transportation

“There’s a great utility in the way the building is set up,” Fowlks said.

The warehouse has EV charging stations which are important as BART includes more EVs in its nonrevenue vehices

LEED stands for Leadership in Energy and Environmental Design and is a rating system based on points awarded for meeting various benchmarks of green building. BART earned the prestigious LEED certification award through a collaborative effort involving AECOM, Clark Construction Group, The Allen Group/TRC Companies and BART’s Sustainability Group. Highlights of the Central Warehouse Project include:

SITE

· Bicycle racks and lockers are provided along with shower facilities to encourage active transportation.

· Parking includes priority spaces for low-emitting and fuel-efficient vehicles, as well as electric vehicle charging stations.

· Bioswales are designed to capture stormwater to reduce runoff and improve water quality.

· High solar-reflectance roof minimizes heat island effect.

BUILDING SYSTEMS

· The energy reduction strategies include efficient HVAC, lighting, and building envelope design, which reduce energy consumption over 30%.

· Selected refrigerants and HVAC systems minimize impact on ozone depletion and global climate change.

· Water efficient fixtures reduce indoor water consumption over 25%.

· Landscape design and irrigation system reduces outdoor water consumption over 80%.

· Enhanced commissioning was performed to ensure all sustainability building systems are operating as intended.

MATERIAL SELECTION

· Over 30% of total building materials by cost include recycled content.

· Over 20% of total building materials by cost were purchased regionally.

· Over 80% of the limited wood materials by cost is FSC certified.

· 99% of construction waste was diverted from landfills.

INDOOR ENVIRONMENTAL QUALITY

· Design includes optimal ventilation and thermal systems to increase indoor air quality, occupant comfort, and productivity.

· Adjustable lighting and thermal system controls are available to over 80% of individual and shared occupant spaces.

· Permanent entryways, isolated exhaust systems, and MERV 13 filters minimize occupant exposure to hazardous chemicals and pollutants.

· Low-emitting materials were selected and installed.

· Indoor air testing was confirmed to meet LEED standards prior to occupancy.