Update - Sept. 16, 2024: The Earthquake Safety Program, including the Transbay Tube retrofit, has been completed.

Read about the retrofit and hear from the people who made it happen in BART's comprehensive history of the Transbay Tube.

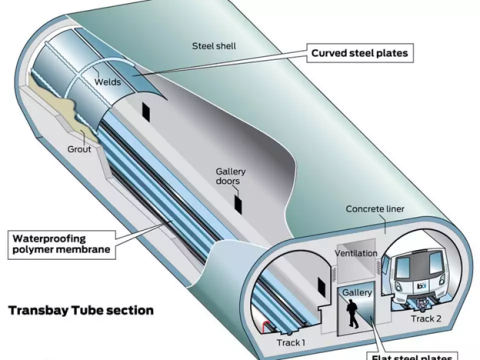

The project involved the installation of a steel liner inside the tube and the installation of a new water pumping system.

The BART Board of Directors awarded a $313 million contract ($267 million base contract with authority to excercise addtional options) on December 1, 2016, to Shimmick Construction and California Engineering Contractors Joint Venture.

The contract's Notice to Proceed date was February 2, 2017.

BART begins pivotal project to strengthen the Transbay Tube

BART’s role in the region as a lifeline was solidified with the 1989 Loma Prieta earthquake. The system was up and running on a 24-hour emergency schedule to serve the public less than 12 hours after the quake hit. It was a watershed event, showcasing infrastructure working for the greater good of the region that paid to build it.

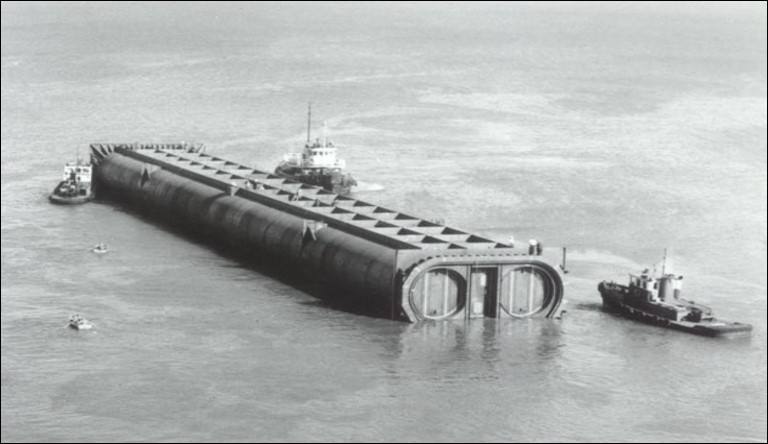

Loma Prieta was centered 55 miles south of San Francisco. Our entire system and the Transbay Tube withstood the shaking. The design and strength of the tube, an engineering marvel sunk into mud in the bottom of the bay, had insulated the train and its passengers from feeling the earth’s movements.

More than a decade later in the early 2000s, BART began to prepare for a major earthquake that could be centered closer to our core system, which runs directly adjacent to the San Andreas and Hayward faults. On November 2, 2004, voters in Contra Costa, San Francisco, and Alameda counties approved Measure AA, which allowed BART to issue general obligation bonds to fund up to $980 million of the $1.2 billion total cost of earthquake safety improvements.

The Earthquake Safety Program addressed the original system completed in 1972 because system extensions built since the early 1970s used more stringent seismic criteria than the original system.

BART's Most Critical Asset

The highest priority for upgrades was the Transbay Tube, BART's most critical asset which opened for passenger service in 1974.

BART worked with earthquake retrofit specialists using a combination of geotechnical and structural site investigations, computer simulations, and testing of materials and models to develop the retrofit design, which was centered around the installation of an inner steel liner and new water pumping system.

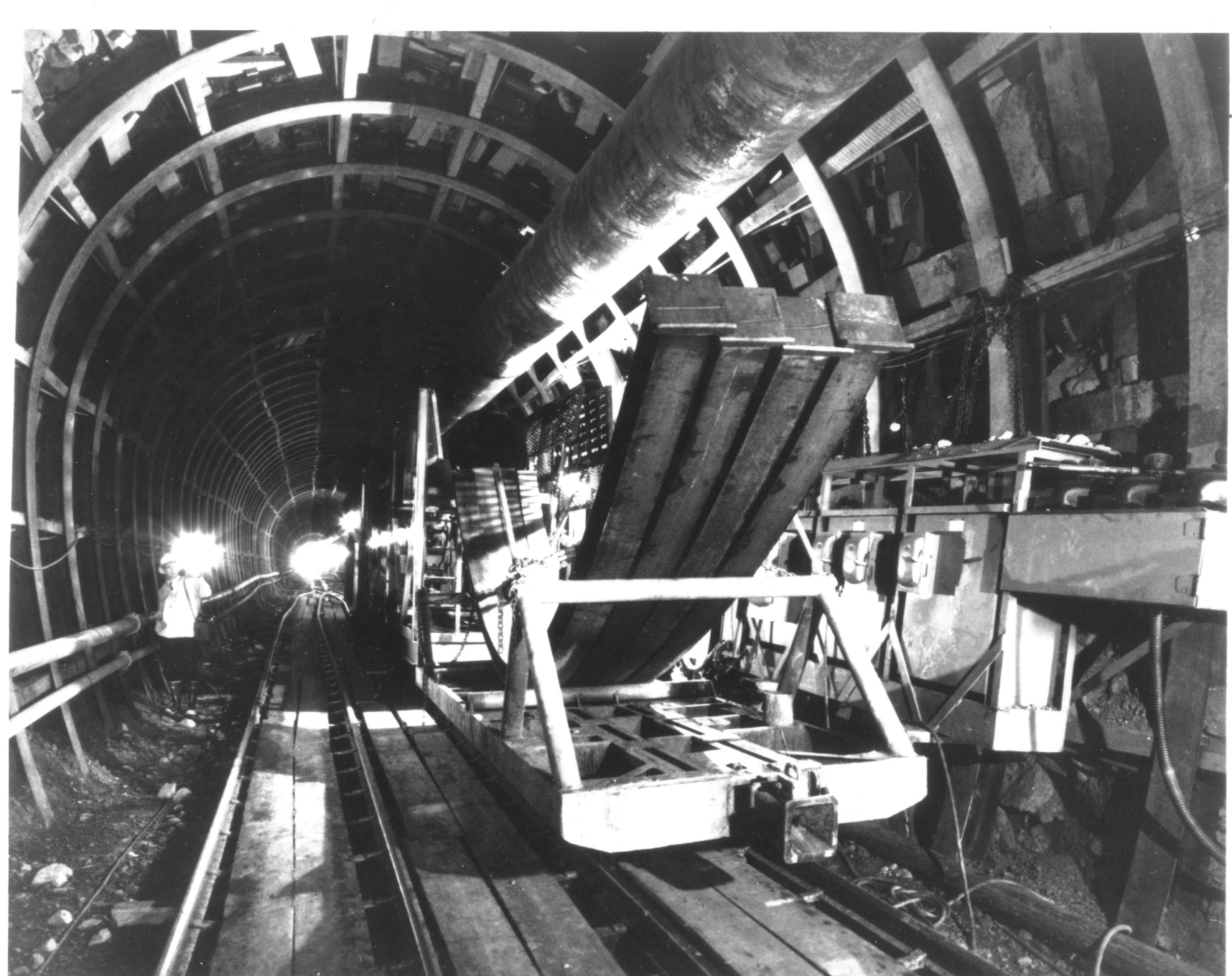

(Inside the Transbay Tube during its construction in the 1960's)

The installation of the inner liner inside of the tube's gallery started in 2017. The next phase began in early 2019. On February 11, 2019, BART shifted from a 4 am to 5 am opening and began single tracking through the tube after 9pm on weekdays to allow more time for the seismic retrofit project.

The Transbay Tube is structurally sound, but we are preparing for a rare and devasting earthquake -- defined as a 1,000-year event -- something that happens once every thousand years. In an event this large, the tube won’t fail, but it could crack and leak.

The retrofit installed a curved inner steel lining to key sections of the 3.6-mile-long tube. It also installed an upgraded pumping system to allow larger quantities of water to be removed quickly from the tube.

A plate handling machine was used to maneuver sections of the steel plates to form archways inside the tube. Once put in place they were welded together and bolted into place. Grout was then be used to adhere the plates to the concrete walls via grout ports in the plates.

Steel plate handling machine similar to one used for the project.

A different technique using a polymer product covered with concrete was used under the tracks.

Locomotive Work Train

The retrofit was done in small sections during a work window of 9:30pm (Sunday-Thursday) until 5:00am (Monday-Friday).

Starting in 2020, crews brought equipment and materials into the tube via a maximum 800-foot long custom-built locomotive work train.

The work train was a critical component of the project. It is made up of three new RELCO clean diesel locomotives and 14 flat cars, with each flat car configured for a specific task. The locomotives bookend the consist, with a third locomotive located in the middle. The work train was designed and fabricated at the RELCO facility in Iowa, specifically to operate on BART gauge rail.

One of three locomotive that make up the Transbay Tube Retrofit Project work train.

There are three 50-foot-long flatcars, seven 40-foot-long flatcars, two 41-foot-long concrete cars, one 55-foot-long steel plate handling device, and one 40-foot-long plate handling device flatcar.

The components of the work train were delivered to BART’s Hayward Shops. It began operations in spring 2020 out of the Oakland Shops. It traveled through Lake Merritt and West Oakland stations before heading into the tube.

Its typical maximum speed is 15 miles per hour, but it runs through switches at five-miles-per-hour or less.

The work train is clean diesel, Tier IV compliant, and meets the latest air quality standards.

Safety checks were done before the Transbay Tube work zone was released to passenger service.