Meet the Fleet: New trains will showcase many environmentally friendly features

Microplug doors save energy by helping with climate control; they also help reduce noise

By RAQUEL CRITES

BART Communications Intern

The engineers tasked with designing BART’s Fleet of the Future faced an unenviable feat: creating train cars even more environmentally friendly than the current ones, which are already among the nation’s best on that score.

“These are going to be extremely energy-efficient cars,” said Henry Kolesar, BART’s group manager for vehicle maintenance engineering. Kolesar and a handful of other top managers and engineers are shepherding the last steps as the Fleet of the Future becomes the fleet of the present.

Four of the new cars are already on site for testing at a Hayward test track, and the first ones that regular passengers can ride are expected to be in service this winter. (For the full timetable go to www.bart.gov/cars.)

Rod Diridon, Sr., retired Emeritus Executive Director of the Mineta Transportation Institute, and an internationally reknowned transit expert, noted that “while the old cars lasted a long time due to their design and great maintenance by the BART staff, the new cars will be even more effective with their unique, sustainable design.”

BAY AREA AN ENVIRONMENTAL GEM

Sustainability is a point of pride because Bay Area residents feel strongly about the special nature of the environment where we live, and the responsibility to be good stewards of it. It is only fitting that the region’s transit system advance its train cars to meet the progressive standards of the sustainable communities it serves. From top to bottom, literally, the new trains have been engineered for high energy-efficiency.

“We had asked for a lot from them (car manufacturer Bombardier), to produce trains that were 7% more energy-efficient that the current ones, and we’re expecting to get something even beyond what they had promised,” Kolesar said.

Among the energy-efficient features:

- · The propulsion system will get among the best efficiency of major transit systems at around 4.5 kilowatt hours per car mile

- · A new traction motor design provides more torque, or turning power, with less energy

- · A unique air-conditioning system uses dual, parallel refrigerant compressors for better climate regulation (important in Bay Area microclimates)

- · Microplug doors provide a tighter seal on climate control and track noise

- · LED lighting throughout the cars, including headlights, is cooler and self-adjusting for light conditions, aerial or underground

Above, LED lights inside the car are self-adjusting for lighting conditions -- they'll be brighter underground and will automatically dim in bright sunlight. Below, an example of an LED headlight on one of the pilot cars in Hayward.

- · The exterior is made of aluminum, which is extremely lightweight and completely recyclable when the cars are eventually dismantled

- · The tops of the cars are white instead of silver to reflect sunlight and reduce heat loads

- · Regenerative braking pumps energy back into the third rail system, even more efficiently than on current cars

BUILDING ON A SOLID FOUNDATION

Kolesar said all these elements together add up to an even more sustainable new train car, building upon one that was itself innovative when it first came into service in 1972.

“BART has always been a leader on the edge of efficiency technology,” he said. “We didn’t want to experiment with entire new concepts that had never been tried before. Instead, we took known technology and pushed it to its limits to get the maximum efficiency.”

Propelling a fully loaded BART train over hills and through tunnels takes power, and lots of it. BART trains are all-electric, running on third-rail power of 1,000 volts.

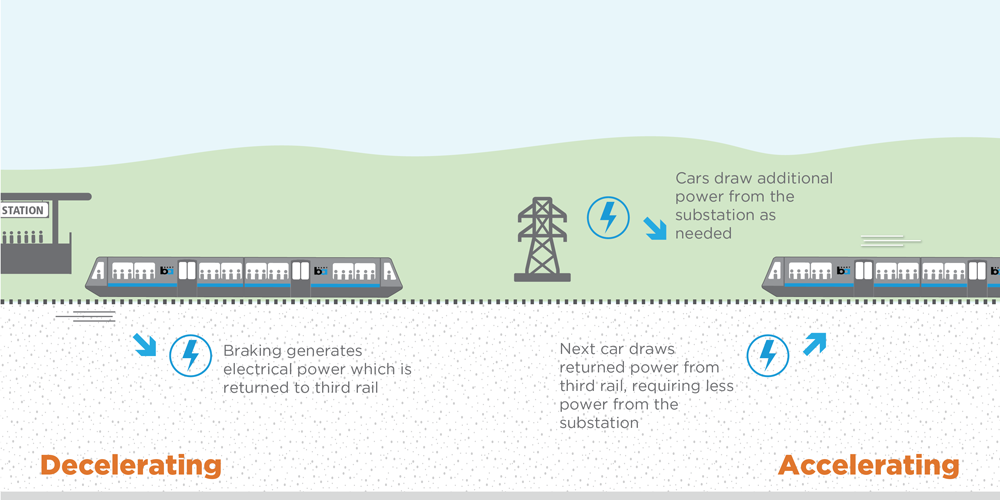

A fully loaded 10-car train accelerating away from a station pulls nearly 10 million watts of electricity, or 7,000 typical hair driers’ worth. Third rail power feeds 40 large electric motors. Each motor (at approximately 1,000 pounds) weighs about a third of a Honda Fit. When the train’s brakes are initiated, those motors instantly turn into generators to feed equally massive amounts of electricity back onto the third rail for other trains nearby to use.

HOW REGENERATIVE BRAKING WORKS

A motor acting as a generator makes a terrific brake. The faster you go, the better it works. Third rails are electrically connected from track to track on both sides of a platform. So, a train slowing as it approaches a station can literally push out a departing train on the other side, reducing the net electrical load on the substation and helping BART recover part of its electricity bill.

In 2015, BART sponsored legislation to allow “direct procurement of renewable energy” and with their energy contracts expiring soon, there is even more of an opportunity to focus on increasing intake from renewable sources, according to a presentation by Holly Gordon, BART’s Sustainability Group Manager.

TESTING PHASE IS UNDERWAY

All of the pilot trains’ features are part of extensive static and dynamic tests to assure safety and reliability before they begin carrying passengers. If aspects are determined not to meet specifications, they can be corrected before all the trains come off the production line and into service. That balancing act is part of procuring any large and expensive system such as these new trains -- making sure to get it right while still remaining in line with the final schedule for delivery of all the cars.

By increasing the capacity of the BART system with an eventual larger number of overall train cars in the fleet, a new train control system and maintenance facility, more riders will be able to leave their vehicles at home as they travel throughout the Bay Area.

A peak-hour BART train gets the equivalent of 249 miles per gallon, far more than even the most efficient commercially available hybrid vehicles. Just one commuter using BART each weekday instead of driving saves over 300 gallons of gas and 6,277 pounds of CO2 in a year. (You can use the carbon calculator on BART’s QuickPlanner to estimate just how much CO2 you are saving by taking public transport).

NEW FLEET WILL ACCOMMODATE MORE GROWTH

“With the Fleet of the Future, our goal is to increase the number of train cars in the BART fleet by 62% to accommodate more people on BART and help them get where they need to go” said Aaron Weinstein, BART Chief Marketing Officer.

“And that, in turn, will help reduce traffic on Bay Area freeways, lessen chemical runoff into the Bay, and improve air quality," Weinstein said.

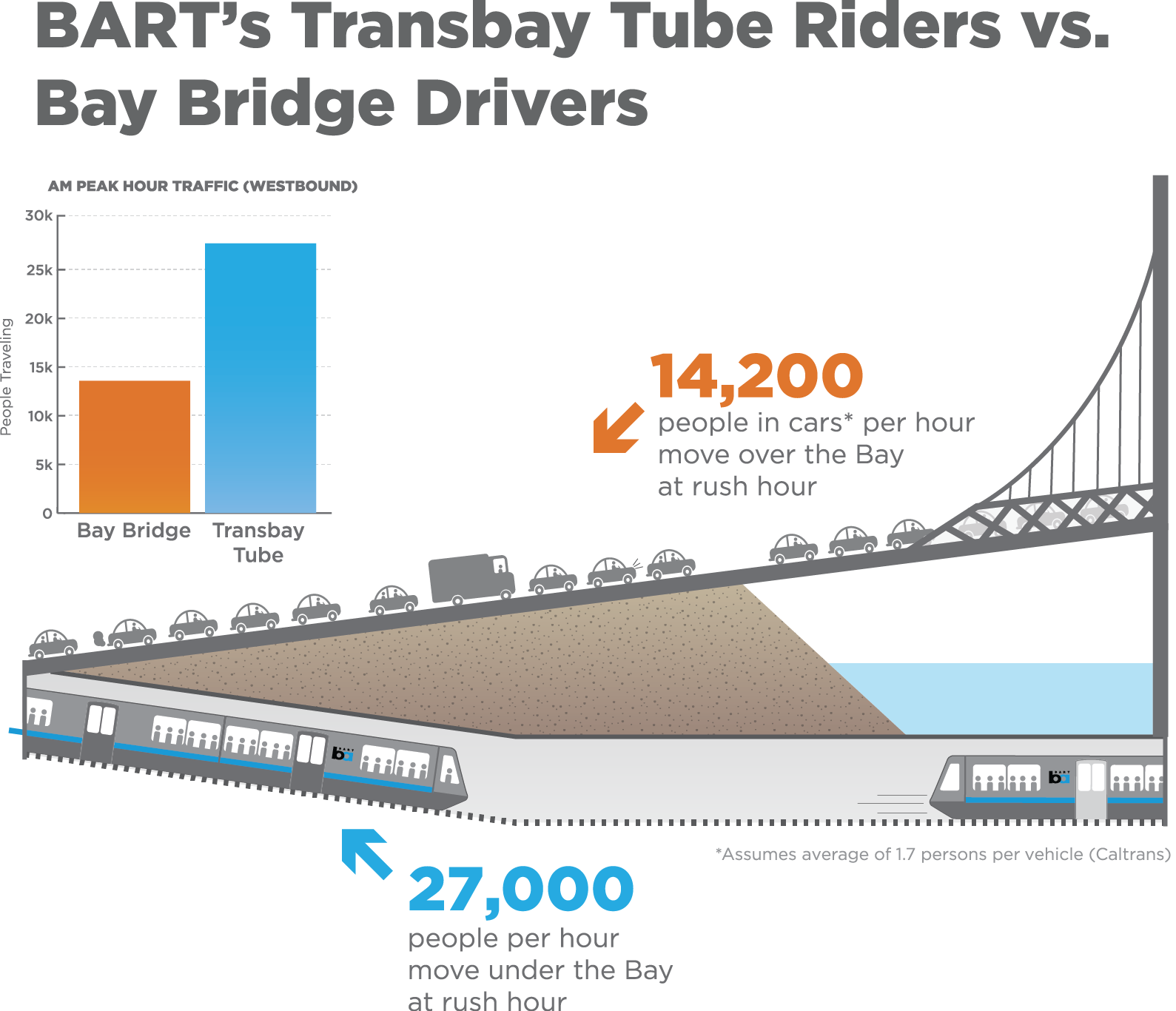

Additionally, looking at the number of people carried back and forth across the Bay between Oakland and San Francisco, BART wins hands-down over vehicles on the Bay Bridge.

It all adds up to a better experience for BART riders, and one they can feel good about making to protect our Bay environment for generations to come.

If you'd like to comment on the new trains, use this email form to reach us.

Meet the Fleet is an occasional ongoing series looking in-depth at different aspects of BART's new train cars. Previous articles that you can read at www.bart.gov/cars include:

Meet the Fleet: Passenger information systems get a big upgrade on new trains

Meet the Fleet: Improved climate control highly anticipated on new trains

Meet the Fleet: New train car gets ready to head West

Meet the Fleet: All about the seats, a firsthand report