Ventilation on BART: What you need to know about airflow and more

Denser air filters like the one shown above are capable of blocking more particles

Read our January 2021 update: After successful pilot, denser filters will be added throughout BART’s fleet of train cars

October 2020 update: Midway through pilot, tests of new filters and UV light on BART show promise

Story by MELISSA JORDAN | Photos by MARIA J. AVILA

BART Communications

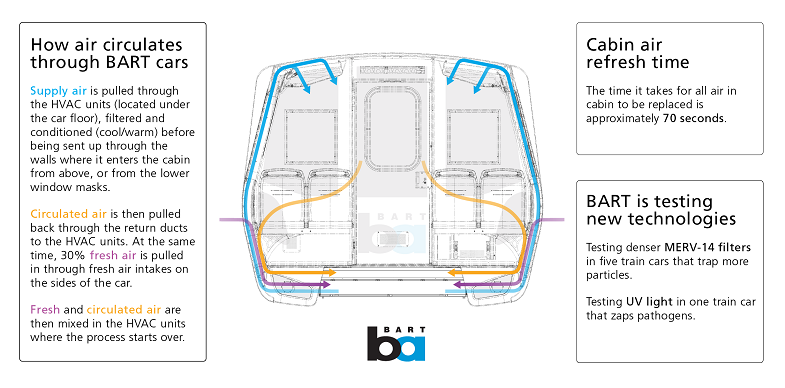

The air you breathe while riding BART is filtered more effectively than that in the typical office or indoor setting like a grocery store or pharmacy, with an entire train car’s air being replaced about every 70 seconds.

That was the case before the Covid-19 pandemic, and it’s even more important now, as BART implements a 15-step Welcome Back Plan with a raft of new health and safety measures.

Because the coronavirus spreads through droplets in the air when a person coughs, sneezes or even just talks, air filtration is key to stopping transmission. Wearing a mask is a first line of protection; BART’s Heating, Ventilation and Air Conditioning (HVAC) system provides another safety layer.

“The BART fleet’s ventilation systems provide passengers with about 4,000 cubic feet per minute of air per car, or about 50 air changes per hour, which is substantial when compared with other public spaces,” said Daniel Cheng, Senior Vehicle Systems Engineer. “All the air is filtered before entering the passenger area.”

BART is also pushing the envelope on what is possible in the area of filtration, with air exchange that compares favorably to other transit systems. Two new pilot projects are being tested at BART in August: a higher-grade, denser filter panel that will trap smaller particles, and an ultraviolet (UV-C) light source inside the HVAC unit that can zap a virus.

Filters in air conditioning systems are rated by their ability to block different-sized particles, a rating known as their minimum efficiency reporting value, or MERV, on a scale from 1 to 20. BART cars currently use MERV-8 filters, which can trap particles between 3 and 10 microns in size and are changed out approximately every three months.

The MERV-14 at left has denser folds than the MERV-8 at right

One of the pilot projects, in five train cars, will test new filters rated at MERV-14 – a denser, tighter weave of materials that will choke off even smaller particles. It’s a careful calculus because if filters are too dense, the air can’t get through without overworking the underlying machinery, which would defeat the purpose if the trains can’t run.

Ben Holland, Manager of Vehicle Systems Engineering, said the MERV-14s passed a component test in the controlled atmosphere of the maintenance shop, and will now be testing in moving train cars.

“What we’re going to evaluate is how quickly do these denser filters become clogged,” he said. “We’ll be asking, ‘How long do they hold up? How long are they effective? Can we stay on the schedule for their preventive maintenance?’ “

The science is not settled on the potential role of particles called aerosols that are smaller than most respiratory droplets. That’s where the ultraviolet light pilot – along with enhanced cleaning and a mask requirement – can help even more.

There’s a solid track record for using ultraviolet light in the ventilation ducts of health care settings to kill microorganisms, Holland said. UV-C light is being tested in one train car.

“UV-C is a proven technology, it’s just not been proven in a dynamic environment,” like a moving BART train, Holland said. HVAC units on BART cars are situated in the undercarriage of the trains and are subject to wear and tear on the rails.

“All of the equipment is underneath the car,” he said. “When the UV lights get bumped around on our rails, are they going to survive?” Crews will monitor the pilot car’s performance over coming weeks and months.

Passengers will not be able to see the new filters or UV-C light on the pilot cars because of their placement underneath the train. (And workers must use personal protective equipment when working with the ultraviolet light, which can damage eyes and skin if left unprotected.)

Overall, the air in BART trains at a given moment is about 75% filtered and 25% fresh air drawn from outside the car (it’s 80/20% on legacy trains and 70/30% on Fleet of the Future trains).

Intake vents draw in air from the outside the car and treat it in the HVAC units, then push the mixed, filtered, cooled air (or warmed during winter) back into the train via vents in the window frame on legacy cars or in the ceiling on new trains. The idea is that larger respiratory drops will be dragged down to fall on floors or other surfaces thanks to gravity. BART’s stepped-up cleaning and disinfecting of surfaces in cars helps further to reduce the chances of transmission.

BART’s not stopping there in the search for good ideas.

“We’ve basically opened the door to talk to anybody and everybody” who has technologies to consider, Holland said. “Going to MERV-14 is more expensive, but it’s not impossible. Installing UV bulbs in HVAC units is relatively expensive, but also highly effective. We’re looking to do things that are practical and effective.”

Fleet of the Future trains have a modernized HVAC system which, in addition to other benefits, includes: total air flow increased from 4000 cubic feet per minute to 4300; supply air ducts on the ceiling for better air flow and more cooling for standees; improved design against refrigerant leakage; and switching from an ozone-depleting refrigerant to an environmentally friendly one.

The modern HVAC units also continually communicate their performance status to the train operator and can provide fault logs and diagnostic functions to help with troubleshooting.

Diagram above: How ventilation works on BART cars, with air being fully exchanged about every 70 seconds

BART, which travels in five different counties with different jurisdictional health orders, requires face coverings for anyone on the trains. Station Agents, BART Police Officers, Civilian Ambassadors and more are handing out free masks to anyone who needs one.

Ridership is slowly creeping up again, after dropping to less than 10% of ridership before the pandemic hit. BART publishes crowding charts every week based on historical data that show social distancing is possible on most trains.

ASHRAE, the professional society for HVAC engineers, has issued guidance that aligns with what BART is testing; the group says MERV-14 filters are preferred in transportation settings, but must first be tested.

“Increased filter efficiency generally results in increased pressure drop through the filter,” ASHRAE says. “Ensure HVAC systems can handle filter upgrades without negative impacts to pressure differentials and/or air flow rates prior to changing filters.”

“A higher pressure drop (from a denser filter) puts more strain on the system; the ventilation system requires more effort to push air through it,” said Moana Reynau, Project Manager at PAE of San Francisco and the communications chair for the Golden Gate ASHRAE chapter.

BART also is keeping in mind worker safety, as employees who install, inspect or replace HVAC filters must have adequate personal protective equipment, or PPE, to keep them safe, as well.

“We are very open to new ideas,” Holland said. “One of the takeaways (of Covid-19) is that we are constantly looking at new technologies and evaluating them.”